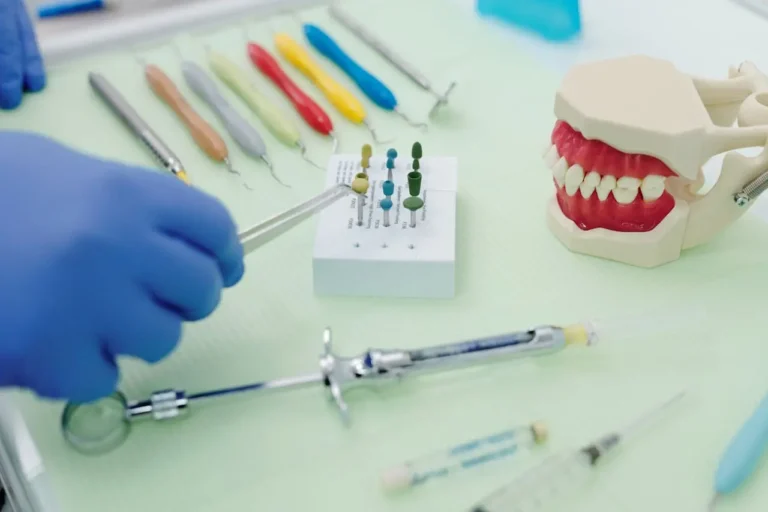

Siemens Healthineers is revolutionizing clinical lab automation by consolidating 25 tasks typically performed manually by staff, significantly reducing manual workflow steps by 75%.

Traditional lab automation relies on a track system to transport samples, but the Atellica Integrated Automation system integrates sample management, decapping, and sealing directly within the Atellica CI Analyzer. This innovation allows labs with lower patient volumes or limited space to access automation previously reserved for high-capacity labs.

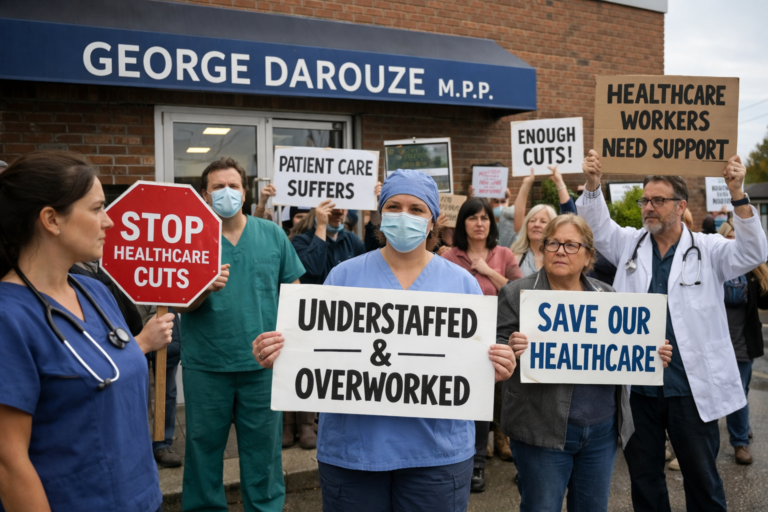

As patient testing demands increase and staffing shortages worsen—vacancy rates in U.S. labs are estimated at 7–11%, and up to 25% in some areas—Atellica Integrated Automation serves as an additional resource for lab professionals.

“Effective automation meets the specific needs of labs, standardizing routine tasks to ensure quality and safety,” said Sharon Bracken, head of Diagnostics at Siemens Healthineers. “When implemented with stakeholder input, it can save time, enhance test quality, and create a safer working environment.”

Repetitive tasks hinder lab efficiency, yet 95% of lab professionals believe automation can improve patient care. Atellica Integrated Automation allows a single technologist to manage essential tasks in minutes instead of hours, freeing up time for more valuable activities like training and quality control.

This automation also minimizes waste and expands testing capabilities, reducing reliance on outsourced samples that can delay results and introduce errors. With optimized sample handling, 65% of samples achieve faster turnaround times compared to competitor systems.

Bracken emphasized that laboratory staff deserve technology that enables them to overcome growth challenges and enhance patient care in their communities. Atellica Integrated Automation is compatible with both the Atellica Solution and the Atellica CI Analyzer, offering flexible automation options to boost efficiency and throughput. For more information, visit the Siemens Healthineers website.